The Importance of Metrology in Manufacturing

In the world of modern manufacturing, precision is everything. From aerospace to automotive industries, accurate measurement underpins every […]

In the world of modern manufacturing, precision is everything. From aerospace to automotive industries, accurate measurement underpins every […]

Height gauges are essential tools in precision engineering and manufacturing. Various types are available, ranging from simple manual […]

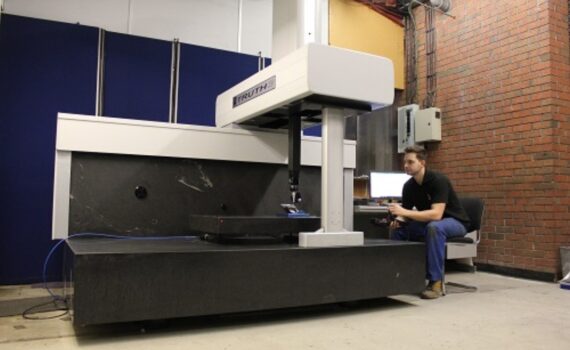

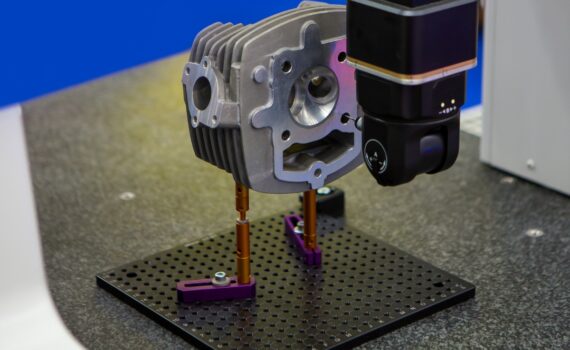

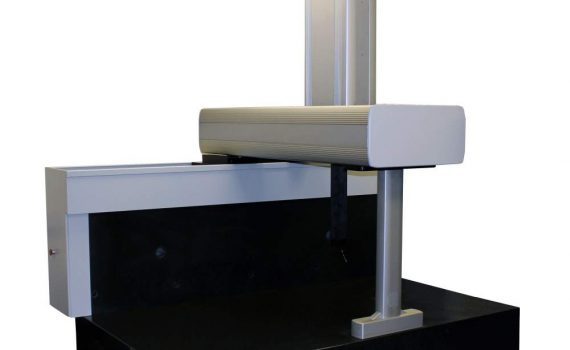

Precision engineering in manufacturing is critical for ensuring product quality and consistency. Coordinate Measuring Machines (CMMs) are among […]

Through the application of science, technology and mathematics, engineers provide solutions to real-world problems. But why is metrology, […]

Without universally accepted measurement standards within various global trades, measurement discrepancies would lead to errors, inefficiencies and safety […]

Metrology – the science of measurement – has proven indispensable to science and industry. It has a crucial […]

Following 2024, 2025 is forecasted to evolve its technological advancement with equal force. Recent hype will manifest itself […]

Today’s young minds are tomorrow’s problem solvers. Enhancing a young mind’s passion for engineering can unlock their future […]

In any scientific or technical field, accuracy and precision are critical aspects of measurement. However, various factors can […]

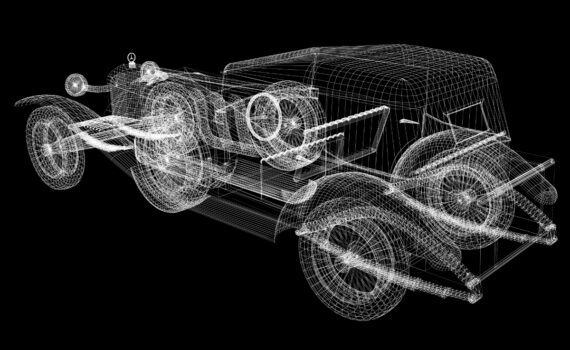

Some cars stand out as milestones in the automotive history of engineering due to their groundbreaking technology, design, […]

Manufacturing is an industry that requires a high degree of human competence and a large amount of working […]

Quality control is an aspect of manufacturing that helps to safeguard against poor performance and its consequences, such […]

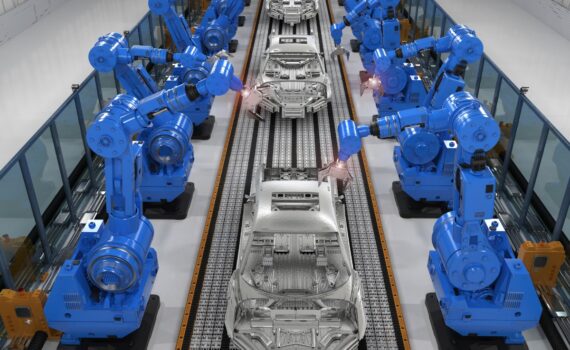

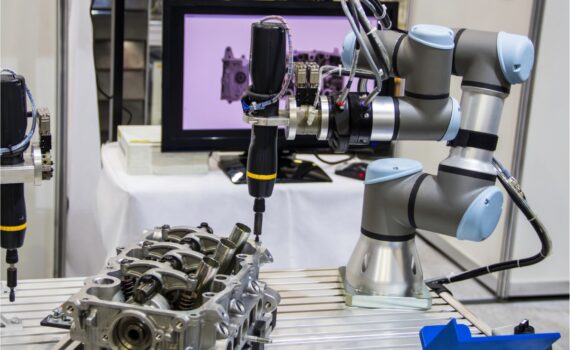

Industrial automation in metrology, the science of measurement, revolutionised how manufacturers ensure quality and accuracy in their processes. […]

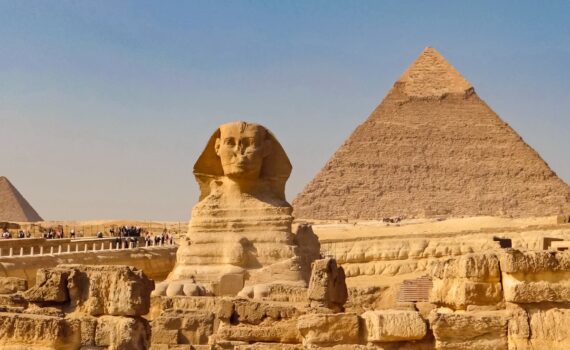

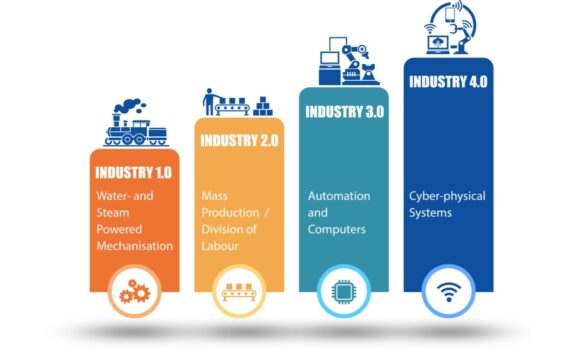

Measurement has been critical to the development and progression of life since very early times. Under the guise […]

Poka-Yoke is a methodology used in the manufacturing industry to enhance quality control by preventing errors before they […]

Metrology, the science of measurement, stands as a fundamental discipline whose evolution mirrors the advancement of human civilisation […]

Robotics technology, characterised by its precision, speed and reliability, is revolutionising traditional manufacturing processes, enabling businesses to meet […]

As people, we rely heavily on measurements for innovation, well-being and prosperity throughout our modern lives. We also […]

The year 2023 highlighted opportunities and challenges that manufacturing will experience in 2024. It was a year when […]

Metrology is the science of measurement. Calibration is a practice that ensures the accuracy and precision of the […]

The manufacturing industry is undergoing a transformative phase fuelled by the power of Artificial Intelligence (AI). From robotic […]

Toyota’s 5S methodology, also known as the 5S System or 5S Lean, is a set of workplace organisation […]

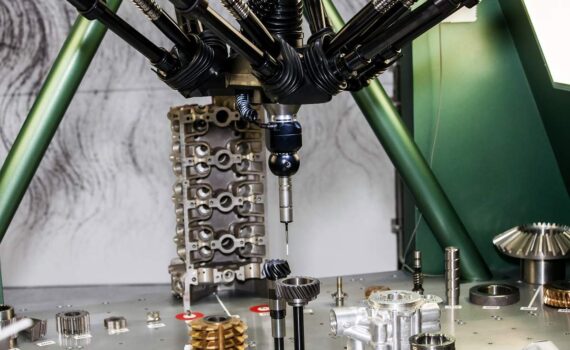

Metrology plays a vital role in the automotive industry to help ensure the success of products delivered to […]

Very often, a coordinate measuring machine (CMM) is the chosen equipment to conduct measurements and compare known quantities […]

A precisely flat surface is often required within science and engineering for various use cases, such as the […]

Within manufacturing, engineering and other fields where measurement matters, it is essential to know how close a measurement […]

Within the fields of science and engineering, there exists an array of practices where precision is vital. One […]

Unsurprisingly, in recent times, manufacturing has been cited as a strategic target for carbon footprint reduction. In 2020, […]

In many manufacturing plants, you can’t move for waste. Manufacturing defects waste materials, products waste time sitting in […]

Manufacturing evolves every year, and professionals in the sector know all about its dynamism and innovation. What we […]

Quality is synonymous with successful businesses. However, nobody’s perfect. We’ve all felt that disappointment when your plans don’t […]

CMM calibration forms an essential link in the chain of production, and it’s done so for half a […]

Precision engineering requires tight tolerance and high-quality machining, and that’s where metrology comes in. Metrology, or the science […]

Optical metrology makes light work of precision measurements in more sense than one. Optical technology delivers fast, accurate […]

We all stress the importance of quality and how engineers, businesses, and clients value it more than ever. […]

Humanity owes a lot to granite. As a natural substance, it’s rich with important properties for engineering and […]

As a relative newcomer to the UK design and manufacturing industries, 3D printing is already taking the market […]

Unlike many modern businesses, manufacturing cannot be conducted with a smartphone in an entrepreneur’s bedroom. Instead, the manufacturing […]

Industries must adapt to survive, and air travel is no exception. Design, software, entertainment, and energy innovations constantly […]

Granite, albeit a humble stone, earns its place as one of the most essential materials in human history. […]

We’ve already passed Back to the Future’s imaginary 2015, meaning that every year from now on is technically […]

Scientific metrology uses precision measurement for high-stakes industrial engineering, from medical equipment to weapons-grade defence infrastructure. However, we […]

To maintain their high standards, workshops and factories must maintain their machines. The most useful machines get used […]

Manufacturing and engineering industries rely on accurate measurements to create reliable readings and safe products. In high stakes, […]

Successful engineers and manufacturers use robust quality control measures to streamline and optimise production. Beyond the morality and […]

Engineering and manufacturing span a wide range of industries, but every workshop requires maintenance, repair, and calibration for […]

Sine plates and sine bars help designers and engineers measure angles, an essential job in any workshop. The […]

The digital height gauge‘s versatility and precision make it a staple of any machining operation. From the simple need […]

Eley Metrology has been at the forefront of the CMM market in the UK for over 40 years. […]

Lean manufacturing is a production method that eliminates waste without sacrificing productivity. It was pioneered by the Toyota […]

Following crisis after crisis, the world needs a less explosive energy solution than fossil fuels. Combustion engines are […]

Design engineers and manufacturers use coordinate metrology to precisely measure the features of machine parts. By mapping coordinates […]

Although it was the Wright Brothers who famously took flight for the first time in 1903, the story […]

CMM interim checks are important to safeguard your equipment and to make sure your machine operates appropriately in […]

Coordinated measuring machines were invented as a precision measurement tool, and for a while, they were considered the […]

Surface plates and tables were one of the first types of metrology equipment. In 1800 British Inventor Henry […]

The foundation of precision measurement is the surface plate. Granite surface plates are considered the more superior material […]

In the exciting and speed-focused world of motorsports, you wouldn’t instantly appreciate the important role of metrology in […]

With so much our time spent in front of screens, scientists and toy developers have been working on […]

If you’re reading this blog, it’s probably fair to say that you have at least an interest in […]

To determine if an item is fit for use, humans have always used inspection. Before the era of […]

Last month, we looked at height gauges, from their origins to the different types of mechanical and digital […]

A Coordinate Measuring Machine is defined by the ability of its probe. As with CMMs, there are several […]

Calibration Calibration is the comparison of a measuring instrument, the unit under test (UUT) to an appropriate standard […]

The robots are coming, and they are taking over the world. Well, that is the popular misconception about […]

There is a misconception that Britain is a nation of shopkeepers. The manufacturing industry is rarely mentioned in […]

A Coordinate Measuring Machine (CMM) is a flexible measuring device used in the measurement of the physical geometrical […]

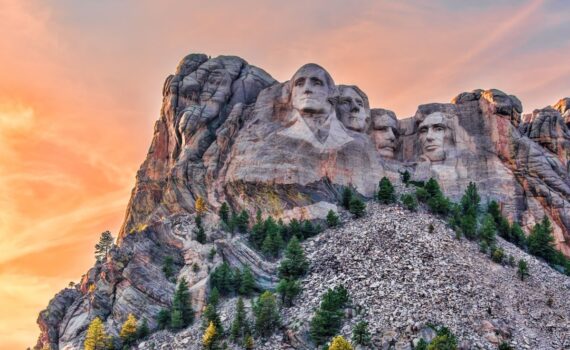

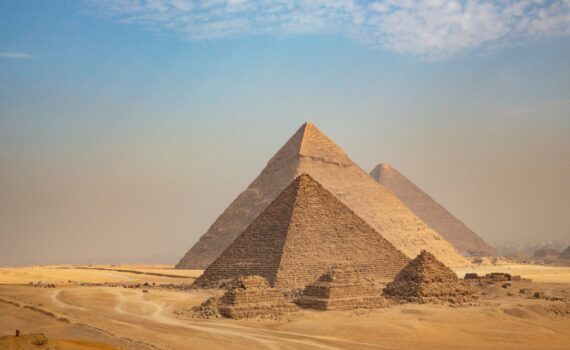

For centuries engineers have created the most impressive infrastructures around the world. From the pyramids in Egypt to […]

What is Metrology? Metrology is the science of measurement and can sometimes be overlooked despite being an essential […]

Is it Possible to Make an Electric Passenger Plane? Some of the leading airlines and engine manufacturers are […]

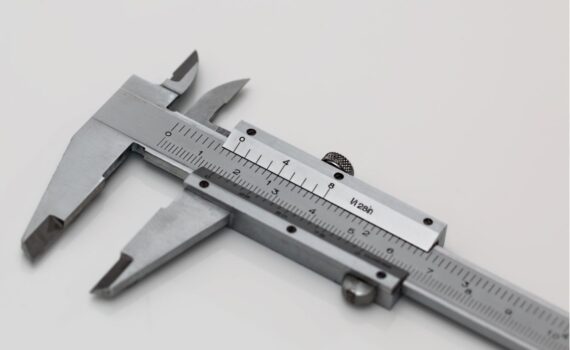

As long ago as 1631, Pierre Vernier, a French scientist, mathematician and engineer invented the “Vernier scale” and […]

What Qualifications Will I Need? If you’ve set your heart on a job in engineering then there are […]

As a UKAS Accredited Laboratory, Eley Metrology ensures their products are of the highest quality and pride themselves […]