As a relative newcomer to the UK design and manufacturing industries, 3D printing is already taking the market by storm. It matches the nation’s drive for flexibility, dynamism, and innovation, so much that filamentive found 44% of Europe’s demand for 3D printing taken up by British markets. But how accurate are 3D printers, and how do the different types measure up against each other? Before we get into that, let’s explore the technology’s uses across different industries.

3D Printing in UK Manufacturing

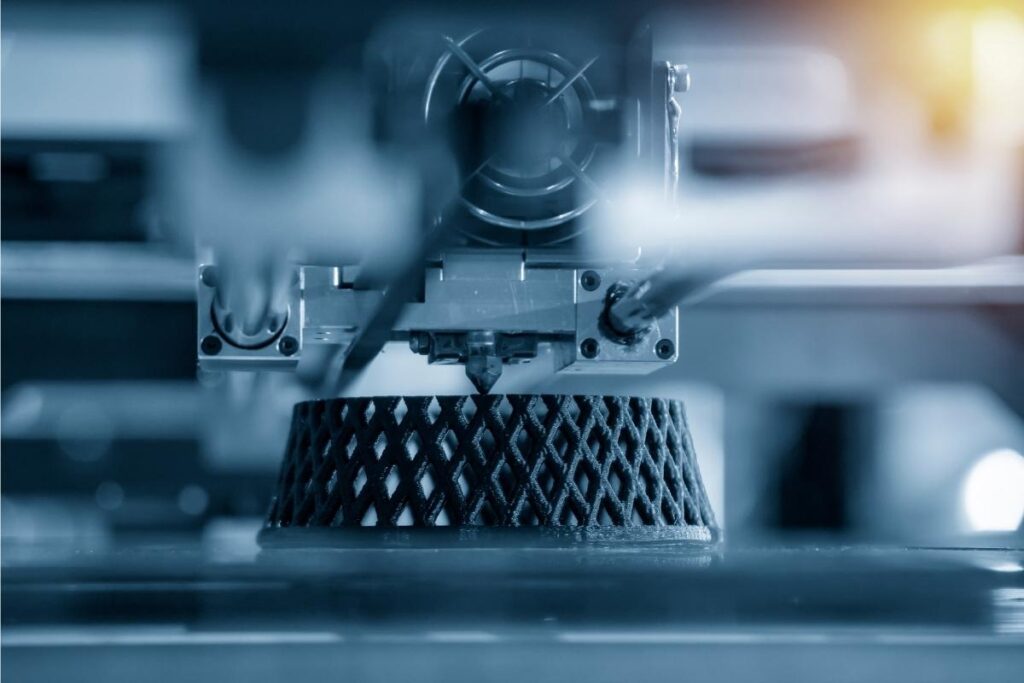

This technology uses thermal and chemical engineering to create custom parts automatically from digital designs on demand. The customisation 3D printing delivers helps it fit the human form, opening new doors in prosthetics and orthodontics.

With 3D design’s radical adjustability, inventors iterate on their prototypes. Printing’s replicability and high-quality ushers it into the factories of high-end brands like Rolls Royce. However, engineers and designers must monitor 3D printing’s accuracy to maintain this high quality.

Accuracy and Tolerance in 3D Printing

3D printers deliver incredibly creative tools into an engineer’s hands, but they’re not perfect. Crucially, some offer more accuracy. In a 3D printing context, accuracy refers to the differences between your digital design and the finished object you pick up off the printing bed. Tolerances refer to the average deviation to expect from each 3D printer’s workload.

Different 3D Printing Technologies and Tolerances

Common 3D printing formats include FDM, SLA, and SLS. Understanding each type helps you understand their accuracy and their best uses.

- FDM – Fused Deposition Modelling printers extrude plastic filament through a heated nozzle into layers on the printing bed. It’s the most common type of 3D printer, used by hobbyists and industrial giants alike. FDM printers deliver tolerances around ±0.2%.

- SLA – Another hugely popular system, Stereolithography (SLA), uses lasers to cure liquid resin into solid plastic. Typically, an SLA platform pulls solid layers up out of a tank of liquid to form your design. This can lead to warping in unsupported spans, and SLA sees a tolerance of around ±0.5%.

- SLS – Selective Laser Sintering machines use lasers to sinter powdered blends of polymer particles into a chosen 3D model. Lasers lend this technology pin-point accuracy, but warping risks on larger parts deliver a tolerance around ±0.3%.

What Other Factors Affect Tolerance and Accuracy?

It’s not just the printing technique that affects the end product. Every aspect, including what goes in, the production conditions, and the post-production treatment, can change the measurements.

Materials

Different machines use different materials, from thermoplastic filaments and powders to liquid resin and even things like metal or concrete. Each of these must be heated and cooled, causing shrinkage as it expands and contracts. For best results, calculate these changes in your design software, and check the results with precision metrology equipment after printing.

Part Size and Intricacy

Larger parts leave more room for errors, particularly when they’re flat, long, and unsupported. The same goes for intricate parts, with a greater density of critical elements and less room for printing errors.

Finish

Cooling, setting, sanding, chemical treating, and measurement auditing all form parts of a robust post-print procedure. As 3D printing layers set, they may cool and contract unevenly, leading to warping that can cause structural weaknesses requiring attention and remedying.

Conclusions: How 3D Printing and Metrology Work Together

Your print might not always match the design on the first try. Equally, your production line might include a warped layer from time to time. However, the great thing about 3D printing is how well it meshes into the existing legacy of precision measurement equipment and accurate tools for quality assurance. Using systems like a digital height gauge and a coordinate measuring machine, you’ll unlock the full benefits of 3D printing and create precise, reliable, and marketable products.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.