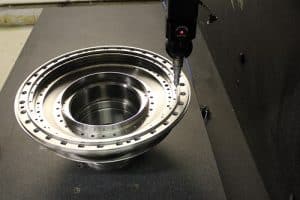

Our market-leading Bridge coordinate measuring machines are verified to ISO 10360 and supported by a UKAS Certificate of Calibration.

Bridge CMMs can be used in virtually any industry where accurate automated measuring is required.

Our team of experts are available should you need after-sales service and support.

We also offer comprehensive service contracts that can also be purchased alongside your Bridge CMM to ensure the smooth operation of your new machine.

Our Range of Bridge CMMs

At Eley Metrology, we have designed two market-leading Bridge CMMs, The Millenium Series Bridge CMM and the Truth S CMM.

Both of our Bridge CMMs are verified to the ISO10360 standard and supported by a UKAS certificate of calibration. The machines are manufactured in the UK at our purpose facility in Derby.

Thanks to our position of having our own UKAS Accredited Laboratory, we can produce tailored versions of both our Bridge CMMs. Alternatively, we can design and build a completely bespoke product specifically for your requirements.

The Millenium Series Bridge CMM

Millennium combines top-class performance with a high degree of accuracy. A fully constrained design, with powerful servo drive units, allows rapid machine movements without compromising accuracy.

Key Features

• Performance verified to ISO10360 standard, prior to and following delivery

• Fully enclosed axes avoid ingress of foreign bodies and greatly reduce temperature gradient errors

• For use in Shop Floor or Standards Room environments

• Non-error mapped, emphasising manufactured excellence

• A comprehensive windows software library

• Quality-combined with high technology performance

• A wide range of sizes available

• Innovation in design. Twin Master beams with Vee Flat guides

• Variable speed control on shopfloor hardened hand box controller

• CAD Communications

• Graphical Off-line Programming, Reverse Engineering

• Batch menu pallet loading offering one button press operation

• Latest controller technology from Renishaw; offering both present and future probe options

• Space-saving design

Truth S Bridge CMM

Truth 'S' will scan regular or irregular contours taking thousands of data points in seconds while also offering conventional CMM touch-trigger technology.

Key Features

• Truth 'S' is verified and certified in accordance with ISO 10360, the international standard for CMM's, and offers a performance second to none.

• A highly developed software and control system harnesses the unique Truth 'S' electro-mechanical construction.

• Precision vee-flat guideways are hand-finished to provide extremes of parallelism, straightness and flatness.

• Stability and integrity while actively scanning are provided by a kinematic mounting system, employed throughout the entire mechanical structure.

• The independent Y-axis assembly is unique. It is designed to minimise structural deformation due to inertial forces created while the machine is measuring.

• The unique mechanical design features of the Truth 'S' negate the use of 'error mapping'.

• Quoted specifications are therefore achieved by design and manufacturing excellence.

• All Truth 'S' machines are supported by a UKAS certificate of calibration.

Find Out More

If you’d like more details about our range of Bridge CMM's, then our team are available to help.

Call Us: 01332 367475

Email: sales@eleymet.com

Send your enquiry via our contact form below;

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.