When it comes to measurement in accuracy-focused industries, even the slightest error can lead to costly setbacks.

This article explores why surface plate calibration is a necessary step in maintaining measurement integrity, improving workflow efficiency and ensuring every project meets exacting standards.

What Is a Surface Plate?

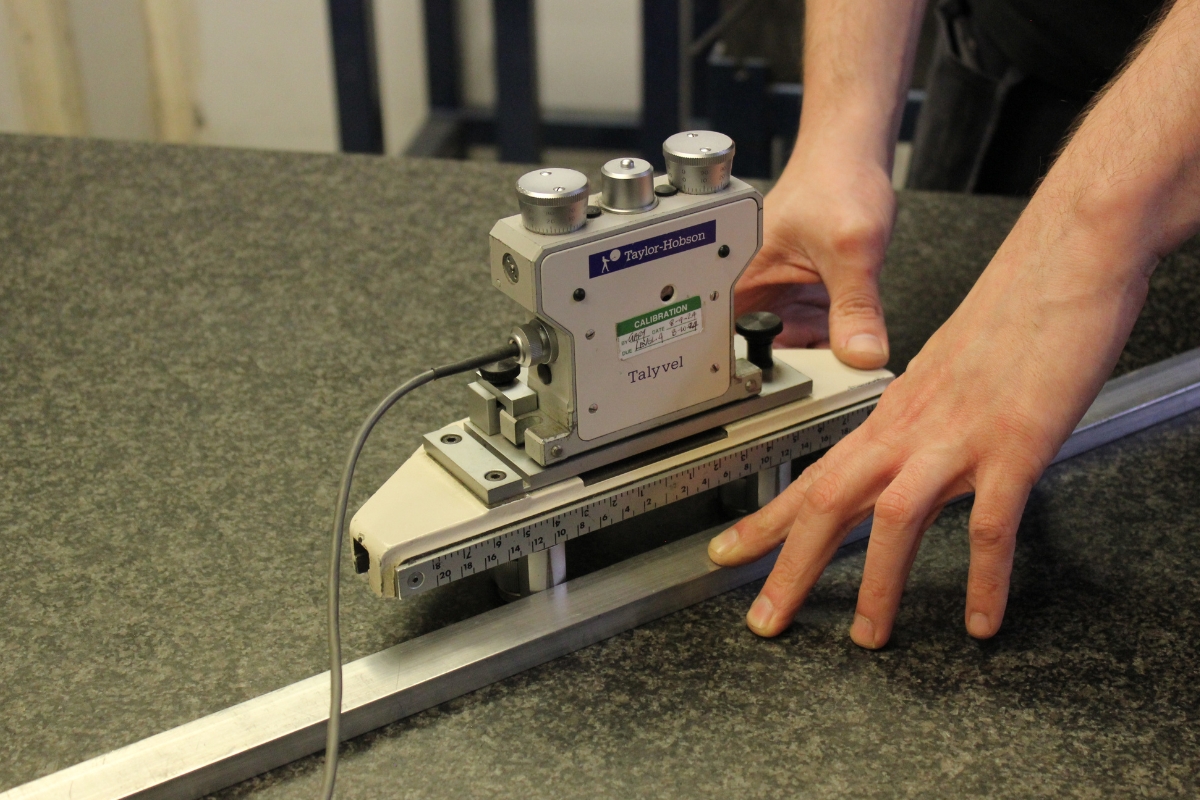

A surface plate is a very flat, precision-made base used to measure and inspect parts with high accuracy and precision. It acts as a reference surface plane, helping engineers and machinists check dimensions, mark out work and set up equipment correctly.

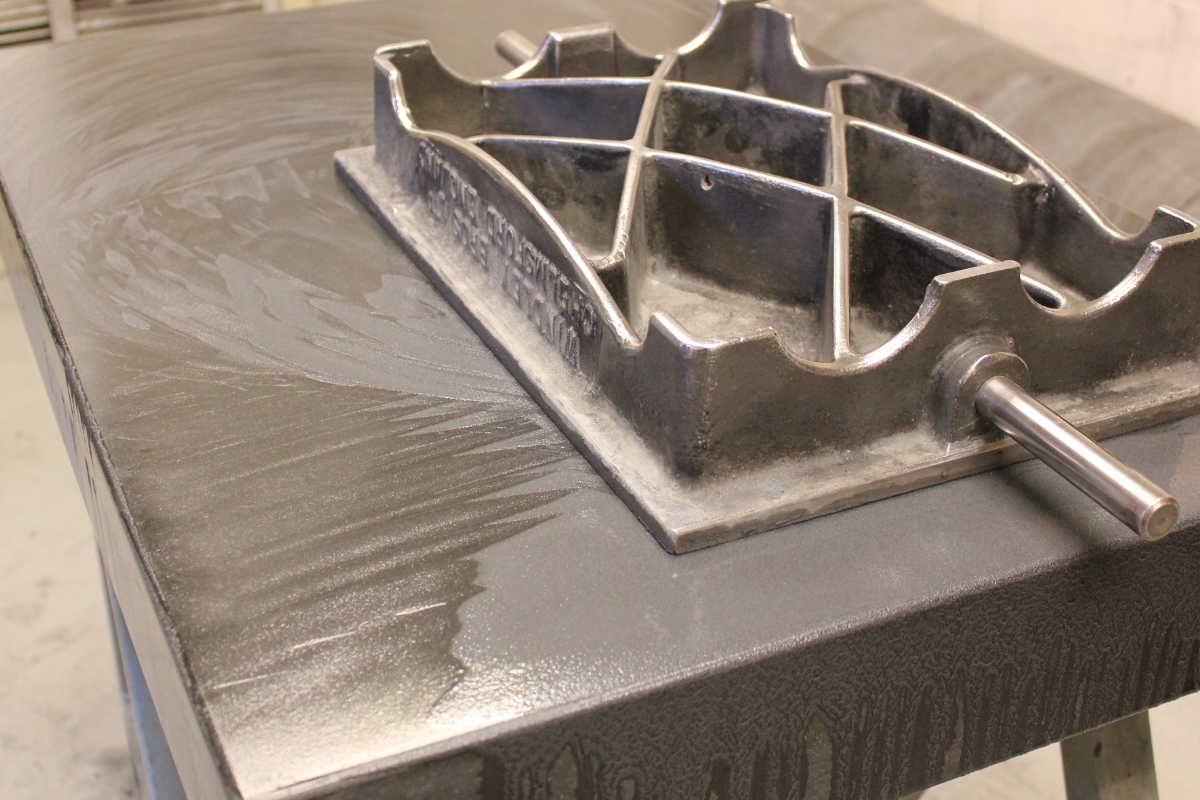

Most surface plates are made from granite, cast iron, or glass, with granite being the most popular due to its strength, stability and resistance to wear, temperature changes and rust. However, even the highest-quality surface plates can wear gradually over time. That’s where surface plate calibration is crucial.

Why Does Calibration Matter?

Calibration verifies that a surface plate remains within its specified flatness tolerance, ensuring measurements taken on it remain accurate and trustworthy. Without calibration, errors can go unnoticed, leading to scrapped parts, failed assemblies or costly rework.

In industries where microns matter, surface plate calibration is essential as it guarantees reliability, extends equipment life, and maintains compliance with quality standards, legal requirements and certifications.

The Importance of Maintenance

With simple, consistent care alongside regular calibration, a surface plate can remain highly accurate for many years, reducing the risk of wear, measurement errors and costly repairs or replacement.

Therefore, regularly clean the surface plate to help prevent dust and metal particles from damaging it. When not in use, keep it covered to protect it from dirt and accidental impacts. Avoid placing heavy items or dropping tools on it, as these can cause dents, scratches or bending.

It’s helpful, and sometimes a requirement, to keep track of calibration dates, condition checks and how often the plate is used to ensure accuracy is maintained and any issues are caught early.

Common Uses of Surface Plates

Manufacturing and Machining

In manufacturing and machining, surface plates help ensure every part is made to the correct size and shape. Machinists use them to check measurements, mark out workpieces and set up tools accurately. Because the surface is entirely flat, it makes it easy to spot errors early, reducing waste and saving time.

Surface plates are used to measure squareness, flatness and parallel surfaces, which are significantly important in CNC machining, where tiny differences matter. During production, parts are often measured relative to the plate to check consistency.

Without a calibrated surface plate, mistakes can spread through batches, causing costly rework. Therefore, regular calibration helps to keep inspections accurate and product quality high.

Automotive Industry

Surface plates are used to provide a steady, accurate base for checking measurements during the design and production of engines, transmissions, safety systems and other vehicle parts. Engineers often use them to inspect parts such as pistons, gears, camshafts and valve components, where even small errors affect performance.

During quality control, surface plate calibration helps ensure that measurements remain reliable when checking wear, alignment and tolerance over time. With accurate surface plates, manufacturers within the automotive industry reduce defects, improve efficiency and meet strict safety and industry standards.

Aerospace and Aviation

Aerospace and aviation require extremely accurate measurements because small mistakes can affect safety, fuel efficiency and overall aircraft performance. As a result, plates such as granite surface plates are required to provide a stable reference for precise measuring equipment during aircraft assembly, testing, and maintenance.

Granite surface plate calibration ensures measurements remain consistent across different builds and service checks. With safety as a top priority, trusted surface plates help manufacturers produce aircraft parts that meet strict certification and performance standards.

Tool and Die Making

Tool and die makers rely on highly flat surfaces to create accurate moulds, dies and cutting tools. A surface plate allows them to inspect punches, cavities, inserts and guide features with great precision. During setup and assembly, they use tools like height gauges and indicators on the plate to check alignment and dimensions.

As accurate dies help produce consistent, high-quality parts and reduce scrap and downtime, calibration is required to prevent measurement errors from affecting finished tools or shortening their lifespan. Because of this, the surface plate is one of the most important tools in die making.

Research and Metrology Laboratories

In research and metrology labs, accuracy is vital for concise results. As lab results influence product development and certification, even minor errors can lead to incorrect conclusions. Therefore, scientists and technicians use surface plates to ensure experiments are accurate, to prototype-test and compare material samples.

Therefore, it is vital to calibrate the plate to ensure it remains accurate and reliable for critical measurements. It’s just as important that the labs maintain a controlled environment and high levels of cleanliness to extend plate life.

Whether checking component tolerances or testing material stability, surface plates help ensure that data is accurate, repeatable and scientifically reliable.

Overall, the importance of surface plate calibration in industry cannot be underestimated. From quality control to prototyping and toolmaking, a flat plane is crucial for the repeated accuracy of measurement.

Without precision in measurement, manufacturing becomes expensive, research and development success rates drop, and safety decreases. Only through consistent calibration can flatness be guaranteed.

Perhaps above all else, safety-critical industries need calibration audits to ensure documented evidence that the plane is, in fact, flat. Legal and regulatory provisions will require an audit trail of all measurements.

Without calibration and certification, this trail will not exist, and the legal risk is then significant.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.