Precision engineering in manufacturing is critical for ensuring product quality and consistency. Coordinate Measuring Machines (CMMs) are among the most reliable instruments used for this purpose.

This article will explore various types of coordinate measuring machines, their unique features and how they can suit different applications, environments and levels of complexity in a modern quality control process.

What is a CMM Used For?

As CMMs measure an object’s physical dimensions and geometric characteristics with a high degree of accuracy, they are typically employed in quality control and assurance environments to verify that parts meet design specifications. These machines support various measurement techniques, including contact probing, non-contact laser scanning and optical imaging.

CMMs are highly valued in industries where minimal human error is critical, such as aerospace, automotive, defence and precision engineering, due to their ability to consistently and repeatably measure dimensions like length, width, height, angles, diameters and spatial relationships between features. As a result, they’re also often integrated into automated production lines to enable real-time monitoring and feedback, contributing to smarter manufacturing systems.

Types of Coordinate Measuring Machines

Bridge CMMs

Due to their high precision, rigidity, and versatility, bridge coordinate measuring machines are among the most widely used CMMs. Their name comes from the bridge-like structure, where the measuring head moves along the X, Y and Z axes.

Typically mounted on a granite base for stability, the bridge design ensures minimal vibration and thermal expansion, which enhances measurement accuracy. These machines can be equipped with contact probes, scanning heads or optical sensors, making them adaptable for a wide range of applications.

This type of CMM is ideal for small to medium-sized components and is commonly found in industries such as automotive, aerospace, and electronics. Its structure provides repeatability and supports fast, efficient, and accurate measurement routines, making it well-suited for controlled environments such as metrology labs.

Ultimately, bridge CMMs remain a top choice for manufacturers who require reliable dimensional verification while maintaining high throughput in quality control processes.

Horizontal Arm CMMs

Horizontal Arm CMMs are specifically designed to measure large and elongated parts. Unlike bridge CMMs, the measuring arm extends horizontally from a vertical column, offering greater accessibility and functionality to wide or long components.

It makes them a vital tool in the automotive, heavy machinery and shipbuilding industries. This structure enables the inspection of parts, such as car bodies and structural beams, without requiring the repositioning of the workpiece.

While it may not be as precise as bridge CMMs due to potential deflection in the horizontal arm, advances in materials and design have significantly improved their stability and performance.

Cantilever CMMs

Cantilever CMMs feature a single column mounted to one side of the measuring table, with the probe arm cantilevered out over the part. This setup, which requires little space, provides access to the workpiece from three sides, making it easy to load, inspect and remove parts quickly.

As a result, they’re well-suited for applications in electronics, medical device manufacturing and fine mechanical engineering, where components are small and measurement accuracy is critical.

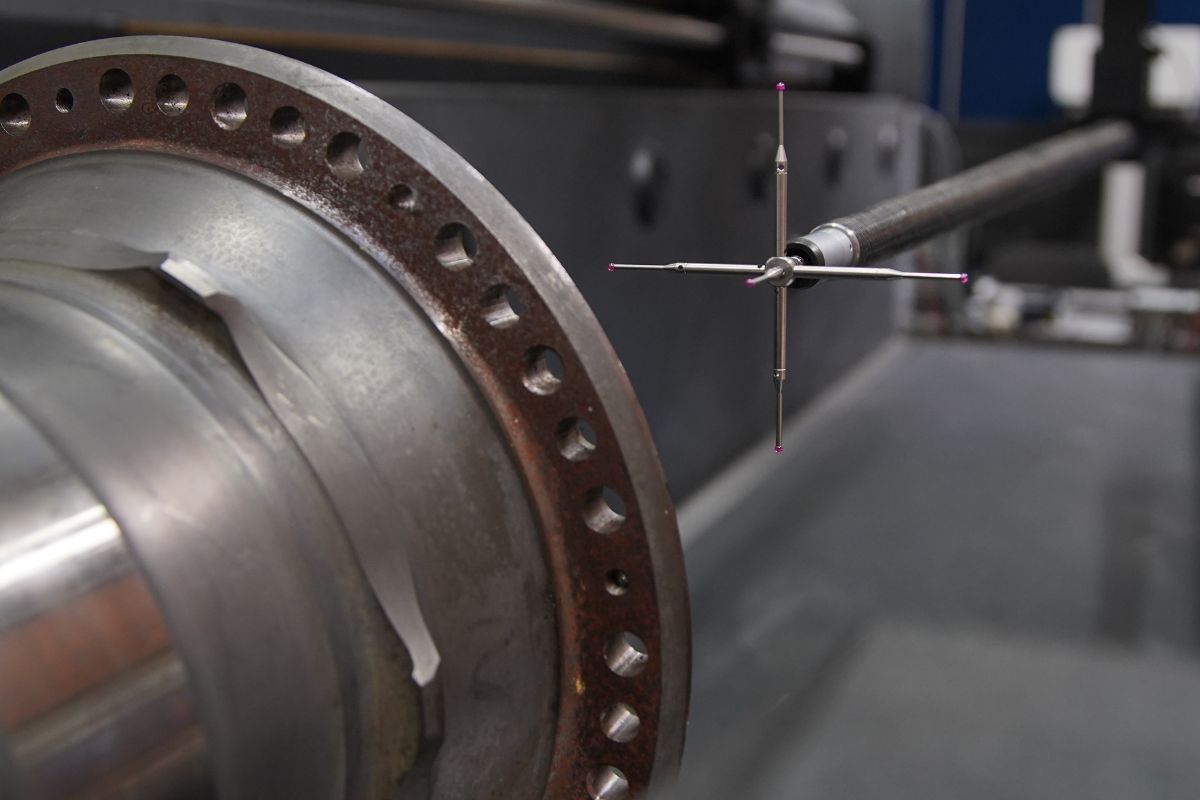

Long Bore CMM

Long Bore CMMs are specialised measuring machines designed to inspect internal features of long, cylindrical components such as pipes, barrels, bores and tubes. Therefore, they’re crucial in industries such as oil and gas, aerospace and defence, where internal dimensions must meet stringent tolerances for optimal performance and safety.

Long bore CMMs provide a practical and effective solution for ensuring the integrity of deep or difficult-to-access geometries in high-performance applications, which standard CMMs cannot reach. They solve this by using extended-reach probes, sometimes mounted on robotic arms or custom-designed fixtures, to measure features deep within the part. They can also incorporate rotary or sliding stages to rotate the component or probe during inspection, allowing complete circumferential scanning and alignment.

Gantry CMMs

Gantry CMMs are large-scale machines designed to measure very large and heavy parts with high accuracy. They operate on a structure similar to bridge CMMs but on a much larger scale, where the bridge is elevated above the part and supported by columns on either side.

This gantry design provides a stable and rigid frame, allowing the CMM to accommodate oversized components without sacrificing precision. Therefore, they’re commonly used in the aerospace, automotive, railway and defence sectors, where large parts, such as aircraft frames, engine blocks and train car components, require a thorough inspection.

These types of coordinate measuring machines can also be equipped with various sensors, including tactile probes and laser scanners, enabling both contact and non-contact measurements.

DeMeet Optical CMMs

DeMeet optical CMMs utilise advanced optical technology like cameras, laser sensors and sophisticated image processing software to capture high-resolution images of the components and convert them into accurate measurements.

As this is done without physical contact, they are ideal for delicate, flexible or micro-scale parts. They are commonly used in industries like electronics, plastics, medical devices and precision engineering. These systems are particularly effective for measuring soft materials, fine features or translucent parts that are difficult to inspect using probes.

DeMeet optical CMMs offer high speed and repeatability, making them excellent for quality assurance in high-throughput environments. Their non-contact nature can also reduce maintenance costs and wear on measuring equipment. With intuitive machine and automation options, this system provides a powerful, user-friendly solution for manufacturers seeking high precision and versatility in their inspection processes.

Custom-designed CMMs

Custom-designed coordinate measuring machines are tailored solutions created to meet highly specific measurement requirements that cannot be satisfied by standard CMM models. These machines are engineered from the ground up or modified from existing platforms and can range from modified bridge or gantry designs to fully robotic systems or portable configurations.

They may also include features such as multiple probing systems, extended arms, environmental enclosures, or integration with automation equipment, including conveyors and robotic arms.

Additionally, custom software may be developed to facilitate specific inspection routines or data reporting formats. Industries such as aerospace, energy and advanced manufacturing often require custom CMMs to inspect one-of-a-kind parts or to integrate into complex production workflows. Though more costly and time-consuming to develop, custom CMMs offer unmatched precision and functionality when off-the-shelf systems fall short.

Consider CMM Measurement Services

For businesses that don’t have the space or budget for CMM technology, Eley Metrology offers subcontract measurement services.

The inspection process can be used for one-off or multiple-batch measurements. By working with metrology experts, businesses can access a full range of CMM and software analysis.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.