Without universally accepted measurement standards within various global trades, measurement discrepancies would lead to errors, inefficiencies and safety hazards.

This article will explore why measurement standards are crucial and how they impact different aspects of daily life.

What is the Purpose of Measurement Standards?

Measurement standards are agreed-upon references that define units of measurement and practices. They are crucial for ensuring accuracy, consistency and reliability across industry, science, trade and everyday life.

Establishing agreed-upon standards helps improve efficiency and quality control, ensures fair transactions in trade and supports seamless international collaboration. They enable trust and interoperability in global systems and ensure that measurements are precise and universally accepted.

History of Measurement Standards

The earliest measurement standard was the cubit, which originated from measuring human body parts like the foot, the distance from the elbow to the top of the middle finger and arm length. Ancient civilisations used and developed it to help with agriculture, construction and trade.

However, as the length and width of body parts differed in size from person to person, the Egyptians devised a solution by using a master cubit to measure the pharaoh’s body parts. This granite block, which was measured to precision so it could be replicated, became known as the Royal Cubit. The workers used this measuring tool to construct the pyramids.

During the rise of the Roman Empire, Julius Caesar gave permission to measure long distances using pace. A double step was equal to five Roman feet, and a Roman mile consisted of 1,000 paces, measured to 5,000 Roman feet. The Romans developed and refined this standard unit of measurement through military conquests, refining it as they travelled across different regions.

By the 18th century, various units were used for weight and measurement, creating inconsistencies that caused challenges when global trade expanded. This prompted the need for standardisation. The French Revolution led to the development of the decimal system in 1799 based on the kilogram and the meter. This laid the framework for modern standardised measurements adopted by many nations.

The 20th century brought further refinement with the establishment of the International System of Units (SI) in 1960, ensuring global uniformity in scientific and industrial applications.

National Measurement System

The National Measurement System is the UK’s infrastructure for measuring science and technology and ensuring traceable and accurate measurement standards. It comprises several institutes and laboratories, such as the National Physical Laboratory, the National Engineering Laboratory and the National Measurement Laboratory. It is delivered through the Department of Science, Innovation and Technology.

Importance of Measurement Accuracy and Reliability

Measurements are consistently performed across all aspects of industry and everyday life to ensure our safety and prosperity. One of the primary benefits of measurement standards is the enhancement of accuracy and precision.

In scientific research, standardised measurements facilitate reproducible experiments and reliable observations. In industry, measurement standards contribute to quality control and process optimisation.

For instance, manufacturing industries rely on standardised measurements to ensure that components fit together perfectly, regardless of where they were produced, reducing waste, improving efficiency, and ultimately leading to higher-quality products. Of course, standards need to exist globally, and domestic and national measurement systems help reinforce this, often adopting and enforcing the International System of Units (SI).

Trade and Commerce

Measurement standards are central to fair and efficient trade practices, reducing trade costs, misunderstandings and disputes. For example, when purchasing fuel, internationally agreed-upon standards will mean consumers can be confident that one litre of fuel in one country is equivalent to one litre in another. When standards are agreed upon, costs are reduced because no conversion between measurements is required. This efficiency is critical to today’s global supply chains.

Safety and Reliability

Some industries, such as nuclear, aeronautical and medicine, are safety-critical. Precision is a matter of life and death, and aspects of metrology such as traceability and calibration are at least regulatory and usually legal requirements.

In medicine, precise measurements are critical for patient safety. From the accurate dosing of medications to the calibration of diagnostic equipment, measurement standards ensure that patients receive consistent and reliable care. Consider the detection and measurement of cancer: oncologists must have trust in the accuracy of measurements.

Environmental monitoring and regulation also heavily rely on measurement standards. Accurate measurement of pollutants, greenhouse gases and other environmental indicators is essential for developing effective policies and assessing their impact. Further, in consumer protection, measurement standards ensure that products meet safety requirements and perform as advertised. When a customer pays for a litre of fuel, they should receive a litre of fuel.

Manufacturing and Engineering

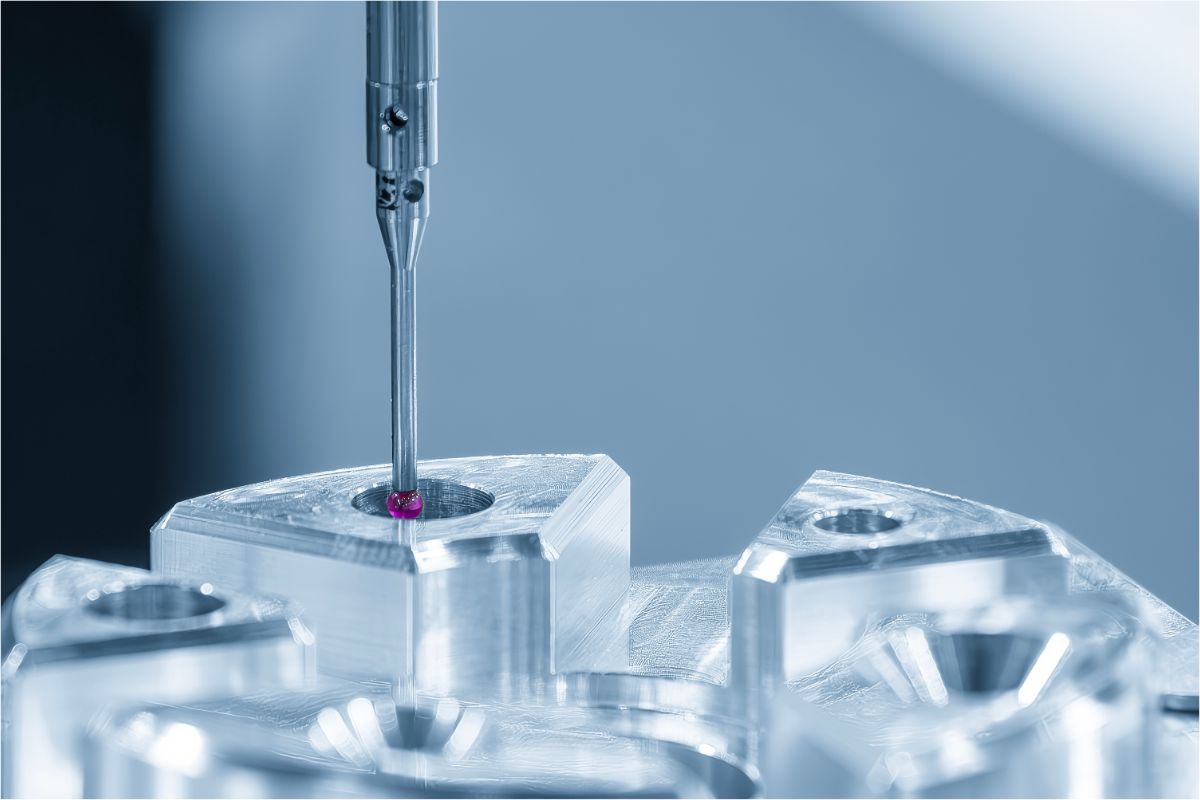

Advances in manufacturing and engineering through the decades yielded systems that utilise componentisation and mass production. The concept of interchangeable parts is heavily dependent on standardised measurements and practices such as equipment calibration. In the aerospace industry, for example, components manufactured in different countries must fit together with extreme precision to ensure the safety and performance of aircraft. Without doing so, catastrophic accidents would be more frequent.

In the electronics industry, the miniaturisation of components has pushed the boundaries of measurement precision. The production of integrated circuits requires measurements at the nanometre scale, where measurements are highly susceptible to error. Hence, standards are critical.

Scientific Research and Development

Scientific progress demands measurement standards to enable researchers to reproduce experiments, validate findings and build upon each other’s work. In fields like nanotechnology and biotechnology, where scientists work at the molecular and atomic levels, precise measurements are essential for understanding and manipulating matter at these scales.

Standardised measurements allow scientists to compare results across different laboratories and countries. This accelerates scientific discovery and fosters international collaboration. From particle physics experiments at CERN to global climate change studies and space exploration at NASA and the ESA, standardised measurements allow scientists to work accurately and precisely towards their shared goals, benefiting everyone.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.