Toyota’s 5S methodology, also known as the 5S System or 5S Lean, is a set of workplace organisation and standardisation principles that originated in Japan and became a fundamental part of Toyota’s production philosophy.

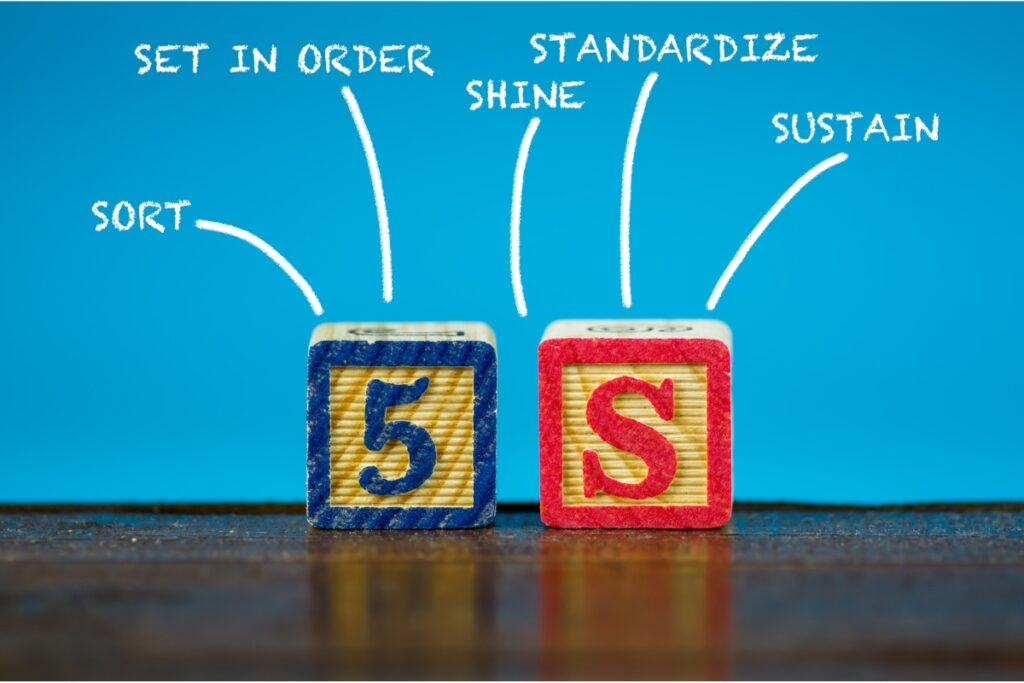

The 5s term refers to 5 Japanese words, each representing one of 5 steps in the methodology. Translated to English, these five words/phrases are:

Sort, Set in Order, Shine, Standardise and Sustain

This article provides an overview of what the 5S system is and how it can benefit companies in the manufacturing industry.

5s Overview

The history of Toyota’s 5S methodology is closely tied to the Toyota Production System (TPS), which Toyota developed in the 1950s to improve efficiency, reduce waste and increase productivity in their manufacturing processes.

The 5S methodology helped create a culture of continuous improvement and waste reduction. It provided a systematic and visual approach to organising the workplace and standardising processes.

Over time, due to the methodology’s contribution to the success of TPS, the 5S methodology gained popularity in manufacturing industries worldwide and became a key component of lean manufacturing practices.

First S – Sort

Sort refers to the first step taken to optimise processes and workspaces. Sorting should rid the working space of unnecessary items such as tools, equipment, furniture and materials; only those required for the task(s) at hand should be retained. This practice will help minimise clutter and the risk of errors, yielding a more productive workspace.

The commencement of this step will involve identifying the items needed for the work area and those that should be moved out. Some items may need to be kept close by and tagged for review if engineers are unsure whether they will be required.

Second S – Set in order

Set in order requires that tools, equipment and materials are stored logically and efficiently within the workspace.

Having a well-defined place for every item will ensure easy access and retrieval. Consequently, engineers and operators will benefit from reduced search times with less likelihood of misplaced or lost tools. Productivity should improve as a result. Health and safety will also improve as clutter, and hazards will be removed.

Many will utilise visual management for this step, allowing any missing tools or anomalies to be quickly identified. For example, the shape of the tool where it should be placed when not in use.

By adhering to the Set in Order step, engineering teams create an environment where tasks flow more smoothly, errors are minimised, and disruptions are reduced. Innovation and problem-solving can then be focused on.

Third S – Shine

Shine promotes cleanliness and the regular maintenance of the workspace and equipment. With a clean workspace, hazards such as damaged equipment and spills can be identified easily. This will contribute to health and safety by reducing the risk of accidents.

If machines and their components are maintained and kept in the best working order, manufacturing will be less error-prone and less costly due to less downtime. Many professional services exist to aid maintenance. CMM inspection services that accurately analyse manufactured components are an example of this, especially when required for regulatory reasons.

Another benefit of the Shine step relates to culture. Engineers and operators are more likely to perform favourably when they take pride in their work environment and equipment.

Fourth S – Standardise

Standardise focuses on developing and implementing work procedures and practices to support the previous steps. It sets the context for 5S being reproducible.

The Sort, Set in Order and Shine tasks can be documented appropriately. Practices can be recorded, and tools created and incorporated into policy and procedures to ensure success. Examples of tools will include checklists for activities such as task completion and audits. Schedules can be made to support continuity.

Training will also form part of this step. Participants of the 5S system need to know about the practices and how to use the tools such as audits. This step could reach as far into the business as necessary to ensure the system’s success.

Fifth S – Sustain

Sustain is about making sure the previous steps continuously happen and improve. This will ensure that the goals of the 5S system, namely continuous improvement and cost reduction, continue to happen.

Culture and management can guide the activities required to achieve the Sustain step. For instance, ensuring that audits, reviews, appropriate training and peer reviews occur.

As a mechanism, Sustain will support an iterative 5S system. All roles conducting activities within the 5S methodology should be reviewed and optimised.

Conclusion

Although incepted within the automotive industry, the 5S Methodology has evolved to many industries operating according to lean manufacturing principles. By promoting an ethos of continuous improvement to support efficiency drives and waste reduction, businesses can focus better on the activities that maximise their opportunity for success.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.