Optical metrology makes light work of precision measurements in more sense than one. Optical technology delivers fast, accurate measurements by using light-based sensors rather than tactile probes. Science is taking vast strides in the 21st century, and engineers require increasingly precise measurement equipment to eliminate errors in their products. Optical CMM systems open a new dimension for designers, manufacturers, and quality controllers. Learning more about this technology can help you and your team shine a light on another field of measurement.

What is Optical Metrology?

Optical metrology covers many principles, techniques, and machines that use light and observation to determine and verify different properties. Some scientists trace its history as far back as the sundial, which uses the sun’s light to determine the time and its passage. However, from measurement apparatus like the telescope and microscope, optical metrology’s tolerances tightened as research advanced. As we’ll discuss, this discipline remains at the forefront of innovation, supporting applications in machine vision, spaceflight, and advanced circuitry.

How Does Optical Metrology Work?

Of course, this technology works differently in different applications. Optical metrology ultimately relies on the speed and stability of light in many of these different cases. Rather than simply peering at things through a lens or observing the way that the sun interacts with things, engineers using optical metrology direct ultra-precise lights and lasers towards objects, and then specialised lenses learn about those objects by the way that the light reflects back.

The Advantages of Optical Metrology

Measuring properties with light unlocks distinct advantages over other metrological practices, such as tactile measurements with probes. Probes come into physical contact with the things they measure and are subject to countless variations in speed, pressure, and more. Optical metrology relies on the constancy of Plank’s constant, and by building on the foundational relationship between the energy and speed of light, it leverages quantum mechanics to understand the world.

Precision

Light is precise. By understanding the speed and refraction of light, and the objects it interacts with, scientists measure tiny yet vital details. Whether you’re detecting microscopic imperfections in a circuit board, fluctuations in temperature, or even nanoseconds on the clock, optical metrology empowers extremely precise readings throughout.

Speed

While industrial machinery isn’t always the fastest thing in the world, light itself is. Optical metrology essentially harnesses the fastest known phenomenon in the universe. This light speed allows the devices relying on it to accelerate their readings. As the discipline develops, optical metrology allows further scaling in speed and processing power.

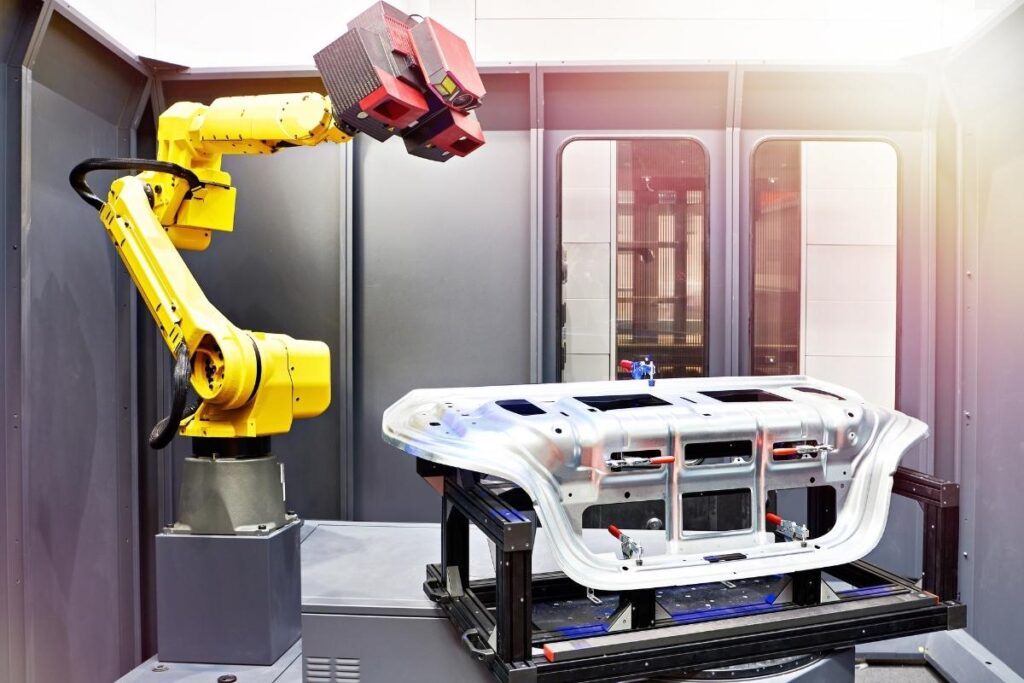

Automation

Scientists develop laser technology in close alignment with automation, artificial intelligence, and 3D modelling. The two technologies go hand in hand, delivering plenty of plug-and-play options for optical metrology. With manoeuvrable equipment and replicable procedures, optical metrology enables ease of use at high standards.

Common Applications of Optical Metrology

Any industry with machinery, wiring, or plumbing requires maintenance, and optical CMM helps workers in any industry maintain their tools. The technology also opens specific opportunities in measurement and chronology, as we’ll explore.

Measurement Tools Like Profilometers

Profilometers scan shapes to detect important surface qualities like flatness, curves, and roughness. Optical profilometers can detect multiple properties with a single image or take multiple images to update engineers in real-time. These applications support quality control on rolling production lines or rapid transition from piece to piece. Industries from electronics to jewellery rely on the measurement prowess of optical profilometers.

Visual Tools like ToF Cameras

ToF (Time of Flight) cameras assist operators and artificial intelligence in analysing space to determine properties like depth and trajectory. They operate like profilometers, sending pulses and measuring the reflections, yet they measure entire scenes rather than specific objects. Scientists are just discovering ToF’s potential with machine vision and beyond.

Clocks

In another remarkable application, optical metrology enables the most accurate clocks known to science. Optical clocks are currently helping researchers redefine the second, relying on light’s frequency to maintain accuracy far more than atomic clocks. With applications in space probes and global positioning systems, photon-based measurements take time-telling far beyond sundials and clockwork cogs.

Temperature Gauges

Optical metrology also supports thermal imaging in measuring heat emissions from bodies, machines, and environments. These temperature gauges help prevent dangerous overheating, keep employees safe, and aid fire safety systems in protecting workplaces.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.