In the world of modern manufacturing, precision is everything. From aerospace to automotive industries, accurate measurement underpins every stage of production, from design through to final inspection.

As manufacturing continues to evolve with advanced technologies and tighter tolerances, the importance of metrology continues to grow, serving as a foundation for efficiency, safety and global competitiveness.

This article examines the significance of metrology in manufacturing and its impact on product quality, process control, and overall operational efficiency.

The Role of Metrology Equipment in Manufacturing

Metrology equipment plays a crucial role in manufacturing by ensuring precision, consistency, and quality control throughout the production process. Accurate measurement tools help detect deviations from design specifications, minimising waste and rework.

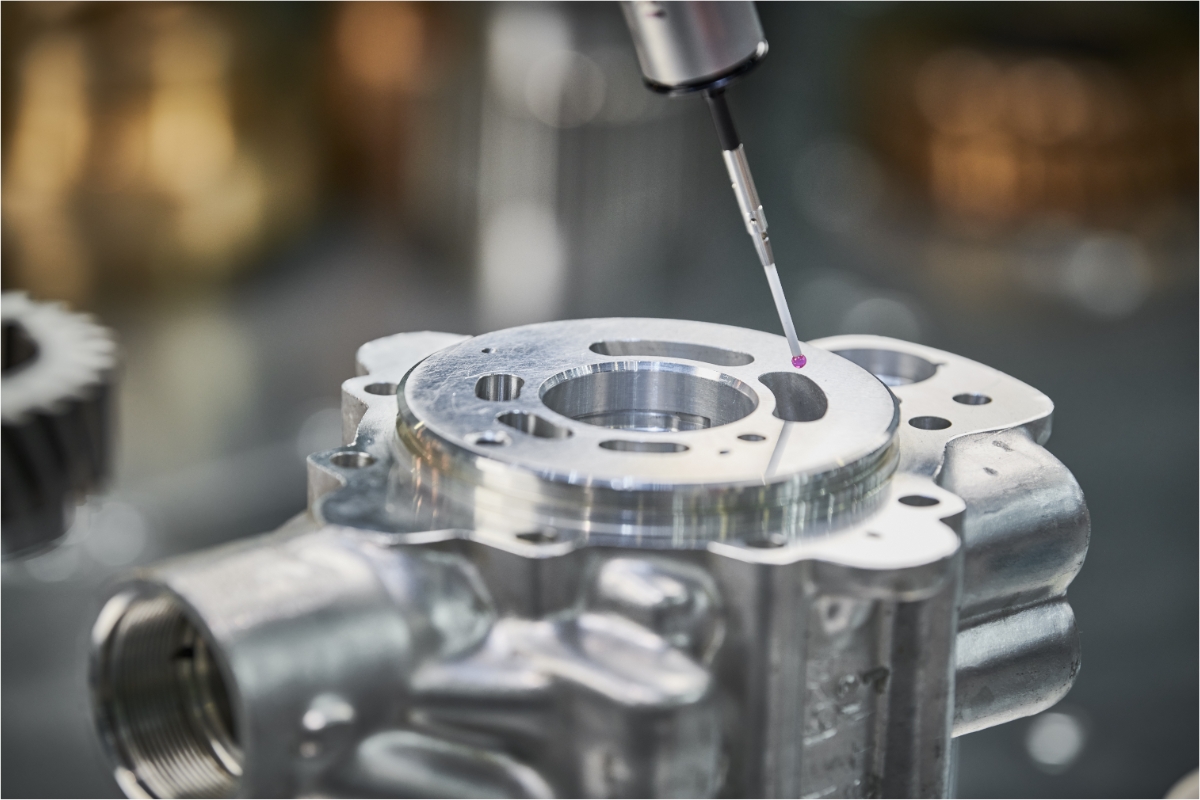

One essential application is the ability to measure identical parts with a CMM, which provides highly precise, automated measurements of complex geometries. This ensures that each manufactured component meets stringent tolerances, supporting high standards in industries such as aerospace, automotive and medical devices.

By enabling data-driven decision-making and maintaining product integrity, metrology equipment can enhance productivity, reduce costs and uphold customer satisfaction.

Why Metrology is Important in Manufacturing:

Ensures Product Quality

Metrology ensures that products meet exact specifications. It utilises measurement tools, such as a height gauge, to verify that each part has the correct size, shape, and tolerances. These measurements are often performed on a granite surface plate, which provides a stable, flat reference surface essential for obtaining accurate and repeatable results.

By identifying problems early, defective parts can be prevented from progressing in production or reaching customers. This protects the brand and ensures products perform well and reliably. In critical industries such as aerospace, medical devices, and automotive, metrology is crucial to delivering safe, high-quality products and preventing costly recalls or failures.

It also supports continuous improvement by providing data that helps engineers refine designs, optimise processes and maintain compliance with strict industry standards.

Reduces Waste and Rework

Mistakes in manufacturing cost time and money. If a part is the wrong size or shape, it often needs to be discarded or reworked. Metrology tools, such as a magnetic V-block , can help prevent this by ensuring parts or tools are prototyped and made correctly the first time.

By securely holding cylindrical or rectangular workpieces during inspection or machining, magnetic V blocks enable accurate positioning and stable measurements, allowing manufacturers to identify errors early and prevent problems from escalating. This not only saves materials but also reduces energy and labour needed for fixes.

Less rework means faster production and fewer delays. In the long run, good metrology saves manufacturing businesses money and helps create a more efficient and responsible method for manufacturing goods.

Enhances Businesses’ Eco-Friendly Practices

When manufacturers measure accurately, they use only the materials they need. As a result, less waste ends up in landfills and fewer raw resources are wasted. Metrology in manufacturing enables machines to run more efficiently, resulting in energy savings and reduced emissions.

Businesses that focus on precision tend to have a smaller environmental footprint. By simply getting measurements right, businesses can do their part to help the planet, thereby building a stronger reputation in the supply chain while still producing high-quality products that their customers can trust.

Supports Process Control

Process control refers to maintaining a consistent and smooth operation within a factory. By measuring parts during production, workers can quickly identify any discrepancies and make adjustments before more significant problems arise.

This keeps the production line steady and reliable, as well as minimises human errors. When processes are under control, fewer products fail, allowing the process to run more efficiently. This makes measurement tools a wise investment for any manufacturing business.

Improves Efficiency and Productivity

Metrology ensures that all components in the production process are precisely calibrated. If machines and parts are precisely measured and maintained, they can operate more efficiently and with fewer errors. That means fewer breakdowns, less rework and quicker turnaround times.

Workers can focus on doing their jobs instead of fixing problems. Ultimately, accurate measurement leads to smoother operations and higher productivity, enabling businesses to meet demand and reduce costs.

Enables Standardisation and Interchangeability

Standardisation means making things the same every time. This is especially important in manufacturing as it helps ensure every piece fits perfectly, even if it was made in another country. When parts are made to the exact measurements, they can be easily swapped or replaced without any issues.

This ability to mix and match parts, known as interchangeability, only works when precise measurements are used throughout the manufacturing process. Whether it’s cars, aeroplanes or computers, metrology helps keep things compatible, reliable and easy to repair or upgrade. It keeps the global manufacturing system connected.

Facilitates Compliance with Regulations

Manufacturing industries must adhere to strict rules and regulations to ensure that products are safe and reliable. Whether it’s food packaging, medical devices or electronics, some laws govern how these products should be manufactured and tested.

Metrology helps businesses stay within those guidelines by providing the accurate measurements needed to prove compliance. Without proper measurements, it’s hard to pass audits or meet certifications. Therefore, metrology not only helps avoid fines or recalls, but it also builds a business’s reputation as a trustworthy manufacturer.

Boosts Customer Confidence

Accurate measurements during production help businesses deliver consistent quality, making customers more likely to trust their brand and enhancing loyalty. Over time, this consistency creates a reputation for reliability. When customers receive products that consistently meet their expectations, it reassures them that the company values quality and attention to detail.

This not only strengthens brand credibility but also gives customers peace of mind, knowing they can count on the product’s performance. In competitive markets, this trust can be a key differentiator that drives long-term success.

Final Thoughts

Metrology in manufacturing plays an important role in ensuring precision, consistency and quality throughout all stages of production. Accurate measurement is the foundation for producing reliable parts, maintaining high standards and meeting industry quotas.

Additionally, it minimises waste, reduces rework and enhances efficiency, ultimately saving time and costs. As manufacturing technologies advance, the demand for high-precision measurement grows. In this context, metrology is not just a technical requirement; it is a strategic asset that drives innovation, operational excellence and long-term business success.

Jeff Eley is the founder and managing director of Eley Metrology, a leading company in the precision measurement industry. With decades of experience in metrology, Jeff has established himself as a respected figure in the field. Under his leadership, Eley Metrology has become renowned for its expertise in coordinate measuring machines (CMMs), digital height gauges, and granite metrology products. Jeff’s vision has driven the company to develop innovative solutions, including custom-designed CMMs and the flagship long-bore measurement machine (LBM). His commitment to excellence and customer-centric approach has positioned Eley Metrology as a trusted provider of high-precision measurement tools and services for industries such as aerospace, automotive, and manufacturing.